Experienced in architecture, fashion and design, Julia Körner combines formulae from the natural landscape with technological advancements.

Imagine a world where the most intricate garments could easily be created on a computer. Rather than producing a pattern, cutting fabric, sewing, adjusting, and so on, a dress could instead be printed, there and then, made to fit your exact body measurements. It might sound futuristic, but this is the real world of Julia Körner, an Austrian architect, and her contemporaries, a group of digital designers whose work in 3D printing and additive manufacturing has the potential to change the way in which fashion is produced.

Körner describes her method as “deeply rooted in interdisciplinary work.” She studied for a degree in architecture, followed by a Masters from the Architectural Association in London, where she became fascinated by geometry and structure, and learned about elements of digital design such as 3D printing and laser cutting, which are now integral to her work. During spells working in New York and London she realised that, whilst in architectural design, 3D printing is largely used for prototypes, in the case of products, “you can actually print the thing you want.”

The move towards fashion, then, seemed logical. Körner wanted to explore “how you could combine traditional creative methods with computational design.” She thinks of this process as “digital craftsmanship,” an apt phrase to describe how she “weaves together couture within the computer.” In 2014, through her work with the 3D printing company Materialise, Körner collaborated on a critically acclaimed collection with Iris van Herpen, a seminal figure who had seen Körner’s interesting patterns and structures, and “wanted something like this remodelled in the form of a dress, so we collaborated on generating the design.” Her role was to create a 3D model of the dress and program its printing. This collaboration was “extremely rich,” Körner says, “it allowed both of us to learn from each other.”

The use of different materials in 3D printing is the key innovation of Körner’s work. Her collaboration with van Herpen produced the first ever 3D flexible print, in the form of the Voltage dress. Prior to this, she had used hard substances: the Hybrid Holism dress, also produced with van Herpen was, she says: “a full-scale 3D print, which came out in two parts, front and back, that are clipped together on the side. It’s a sculptural piece … which really was designed for haute couture and for museums.” The Voltage dress, by comparison, is flowing and organic. It was partly inspired by the process that went into putting together the Hybrid Holism dress – Körner wrote specific code – and then, she says: “we worked out how the flexible material could be enhanced by these calculations. I wrote a script that would digitally map these gradients of lines around the body.”

Eventually, the script which Körner produced for the project “could be adapted and rescaled to any other body form.” Body scanning technology would ultimately allow these pieces to be produced for any shape, and they would fit the wearer perfectly. Indeed, recently, Körner has been working on projects that are focused on “pushing towards how you could make 3D printing more integrated into wearables, how you could eventually combine traditional craftsmanship with digital craftsmanship. I thought it was really interesting, and it’s probably the future of this line.”

In years to come, Körner envisages a process in which “you might not need cutting patterns, or any sort of 2D pattern making.” Instead, 3D scanning of bodies would mean “no need for cutting seams, because you could create continuous surfaces, and print them directly.” The impact of this could fundamentally change the way we shop for clothing: “apart from the idea of customising every single piece, we would also no longer be determined by specific sizes. Eventually, you could get your 3D, individualised garment which is perfectly moulded to your proportions, to the symmetries in your body.” The same idea could also be applied to shoes.

Exciting though this undoubtedly is, Körner cautions against a common reaction: “the first thing people think is ‘I can make anything!’ But it’s not so unlimited: you have to work with the material and the specific technology.” Her garments, as with the Hybrid Holism dress and the Voltage dress are, in part, a dialogue with the available materials, working out what 3D printing is capable of, and how to make the most of it. The capacity to think in terms of “unlimited geometry” is, she acknowledges, “wonderful,” but is “actually very much guided by what’s available from the industry.”

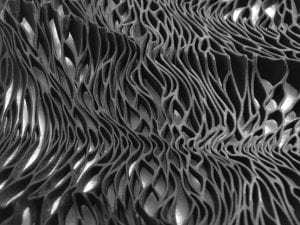

Körner’s personal pieces, like her collaborations, also utilise the potential of new textures. To produce her Kelp dress and Hymenium jacket, she worked with strategists at a US printing company, who focus on a technology which makes it possible to print in different softness and hardness “without changing the thickness of the material.” The resulting product was “very rubber-like, and one of the most technical I had seen.” It allowed her to further develop her fascination with organic structures. For the Kelp Jacket, Körner 3D-scanned foraged kelp: “it was dried, so I could really scan the structure of it. And then I modelled morphologies of it and generated the jacket based on the forms of geometry I found.” This notion of biomimicry allowed Körner to sculpt the jacket “so it looks like the kelp is growing as a second skin.” A similar process took place in the creation of the Hymenium jacket, which is “inspired by the underskin of a Portobello mushroom.” But biomimicry is not an act of simply copying natural structures. Körner did not want the Hymenium jacket to “look like a mushroom,” but rather aimed to “embed the aesthetic capacity of the lamella into the garment.” Essentially, she says: “it should not look like a sculpture, but like something you would wear.”

The inspiration Körner takes from nature has been a longstanding feature. It has not arisen from her work in fashion, but was instead part of her architectural designs in her days as a student, when she was “always looking for, and collecting natural artefacts.” She describes this influence as an “organic language,” and is fascinated by how nature “organises materials … look at deep-sea sponges; they go towards light and build up their structural system based on the water currents and the light. They use a single material to build both their structural grid and their body form.”

The links with her own work are clear; she even designed a dress based on the structural make-up of the sea sponge, where the pattern goes around the whole body, and is more open in places that do not have a structural load. This, she says, was directly influenced by her architectural background, noting that “you can save lots of material with this method.” In this respect, her interest in biomimicry goes beyond the aesthetic concerns and explores the question of how we can extract mathematical logic from nature.

There is clearly, then, a cerebral and highly theoretical side to Körner’s design process, and she does not shy away from dealing with contentious questions about the role of machines in the modern world and what this might mean for our understanding of what it is to be human, and the economic, social and cultural implications which follow from the possibility of mass automation replacing skilled manufacturing jobs on an unprecedented scale. Körner’s designs are data-driven, and so, increasingly, are our lives.

She acknowledges the significance of contemporary debates about “the machine versus the human,” but advocates a more pragmatic, less binary take on the issue. She draws attention to the key role of human creativity in originating the process of design, regardless of what technological tools may be employed in order to realise it. People might, she says, think 3D printing is a case of “there is a computer program, it generates it for you, and then you just send it to the machine, you press a button, and it’s finished,” but in fact, human processes are key to this: “There’s no such thing as a program that just generates designs; it doesn’t exist.” Instead, tools have changed: where designers might have produced a pencil sketch, they now use a digital platform – “but a human is still doing that.”

Ultimately, she believes we should embrace the role of the machine, rather than fear it. This debate after all dates back to the Industrial Revolution, and is unlikely to be settled any time soon. Körner’s view is that machines are in fact more likely to enhance human work than to replace it. “Some people might think negatively,” she says, “that it can take work away from us, or that it would eliminate certain jobs, which is so often the question with robots, for example. But I think it actually adds new opportunities and new ways we can do highly professional things.” For Körner, due to its focus on geometry and symmetry, a machine can “take over some of the things where we as humans might not be as good … we can never be as exact.” This interplay between organic inspiration and machine-produced precision lies at the heart of her couture and is one of its most fascinating aspects.

When she’s not grappling with questions about the future relationship of machines and humankind, Körner is busy researching new substances and technologies to expand the potential scope of her practice. This will, she hopes, allow her to produce wearable garments: “how we could make these things without compromising on geometry” is a major focus for her over the coming year. She has also recently collaborated with a top designer on a big Hollywood production, and is excited by the potential of producing more in this particular design field. More broadly, she is looking at ways of integrating her work into her teaching practice at UCLA, where she is “interested in putting knowledge of other industries back into academia.”

Innovation is ongoing in the field of digital design, and Körner remains excited by its potential: “I like the richness and vastness of what you can find, how you can continually advance and make things work better, improve processes, logistics, materials, and so on. Rather than creating another huge design which just explores geometry, I’m interested in all these other components, too.” Evidently, Körner’s work is set to be influential not only in aesthetic terms, but also academically. Given her influence in this fast-growing field, the fashion revolution of widely available, custom-fit, 3D printed garments might not seem so far away after all.

Anna Feintuck